Earth–Air Heat Exchanger System

An Ecological, Renewable, Sustainable, & Cost-Effective Method of Thermal Comfort

The building sector is responsible for 40% of primary energy consumption, with heating/cooling covering the most significant portion. Thus, passive heating/cooling applications have gained significant ground during the last three decades, with many research activities on the subject. Among passive cooling/heating applications, ground cooling (especially earth-to-air heat exchangers) has been highlighted as a remarkably attractive technological research subject because of its significant contribution to the reduction of heating/cooling energy loads.

The temperature of the earth at a depth of 1.5 to 2 m remains fairly constant throughout the year. This constant temperature is called the earth’s undisturbed temperature. This temperature remains higher than the ambient air temperature in winter and lower than the ambient air temperature in summer.

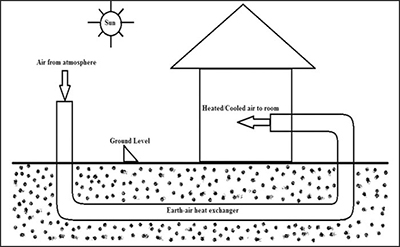

Earth Air Heat Exchanger System (EAHE) is one of the passive technologies which is viable to save a substantial amount of energy in heating and cooling a space with minimal or no negative environmental impacts. It works with the pipes buried underground where intake ambient air comes from the inlet and moves through the underground pipes, and consequently, the intake air exchanges heat under the ground. Then the cooled/ warmed air comes into space through the pipe outlet. An exhaust fan or a heat pump is installed within the pipe to suck the intake air through the inlet.

Components of Earth-Air Heat Exchange Systems:

There are three main components of the Earth Air heat exchange system.

- Blower:

Air from the atmosphere is allowed to enter the Earth’s air heat exchange system (EAHE) through a blower. It sucks the air from the atmosphere and throws it in the system with some pressure just like the ventilator which throws out the room’s air to the atmosphere. It is a fan. A filter can be installed on top of the blower so that the dust particles do not enter the system. The power of the blower varies according to the type of exchange system, area of the house, and diameter of pipes. For a simple residential house, a rule of thumb can be applied.The rule of thumb is that you need at least 1 CFM per square foot of room area. For example, if your room is 15 feet wide and 10 feet long, its square footage is 150. Therefore, it should have a fan rated for at least 150 CFM. - Underground Heath Exchange System:

This is the most fundamental part of the Earth-Air Heat Exchange System. It includes pipes, the diameter of pipes number of pipes, and the types of the piping system. There are different types of Underground heath exchange systems such as parallel pipe systems, series pipe systems, and vertical pipe systems. The details of which will be discussed in later sections. - Outlet Collector/Distribution:

As the name suggests, this is simply an outlet to the room or building. Depending upon the system, distribution pipes can also be used to distribute the air from the collector to different rooms.

Types Of Earth-Air Heat Exchange Systems:

Two different types of EAHEs are used to reduce building energy consumption; they are open and closed loops.

- Open type earth tube heat exchanger:

In an open-loop, intake air comes through the inlet continuously and passes through the pipes buried underground into the room to cool or heat a space and moves out through ventilation. Although the materials used for the loops are extraordinarily durable, it allows heat to transfer to the surroundings efficiently. - Closed Earth Air Heat Exchanger System:

A closed Earth Air Heat Exchanger System where the air is distributed frequently into the room through the underground pipes. No air is exchanged with the outdoor air in this system. It is considered more viable than the open-loop since the cooled/warm air is redistributed inside the pipes covered underground. As a result, the closed-loop can reduce the pipe length used in the EAHE. The loop/pipe length depends on some crucial factors, namely loop configuration type, cooling and heating loads, soil conditions, and local climate. The underground pipes can be set up in slinky, spiral, vertical, horizontal, or even on a water body surface.

Orientation Earth-Air Heat Exchanger Systems:

The orientation of the Earth-Air Heat Exchange system can be classified into three different types depending upon its functions, working and piping system. Each system has its functions and pros and cons.

- A horizontal ground heat exchanger (HGHE):

HGHE loop model involves several connecting pipes/tubes aligned straight and horizontally under the ground either in parallel or series. Parallel tubes are frequently used in this loop as it helps to increase the EAHE performance by reducing pressure drop. In addition, the pipes having smaller diameters are chosen for constructing parallel loops which allows fluid to transfer more heat to its surroundings. The horizontal pipes are typically buried 1 to 2 m below underground.The HGHE system is cost-effective while the pipes are easy to excavate, and sufficient land space is available. It is comparatively easy to install during the construction of a building. However, it can also be installed after construction, for example, in the yard or the driveway. Parallel piping systems are appropriate in achieving better thermal performance for the HGHE system. In the parametric study of pipe materials, copper showed 16% more efficiency in comparison to other conventional pipe materials. Horizontal straight piping layouts were found worthy in terms of overhead costs. - A vertical ground heat exchanger (VGHE):

VGHE loop model consists of a single tube/pipe or several connecting pipes aligned straight and vertically buried underground. This system normally contains high-density polypropylene or polyethylene plastic pipe(s) installed below the ground, backfill material with grout which assists in reducing thermal resistance as well as confirming a good contact between the underground pipes and ground.A vertical ground heat exchanger (VGHE) can be fitted within a limited land space. A VGHE is usually 20 to 300m deep with a diameter of 100–150 mm based on the ground conditions and energy demand of space. It is broadly used to utilize the maximum heat exchange capacity of EAHE when a minimum disturbance is desired for the landscape and/or the earth’s surface is rocky. The VGHE requires fewer pipes to achieve the same efficiency as other EAHEs because of the earth’s constant temperature found at a specific depth under the ground. However, the installation cost is quite expensive as higher excavation is required to install the pipes. - A slinky ground heat exchanger (SLGHE):

The slinky ground heat exchanger loop model comprises several circular tubes/pipes designed as slinky which are installed horizontally or vertically underground. The SLGHE performs well if the underground pipes are orientated vertically. The buried pipes can be overlapped or separated from one to another. In the case of the overlapping piping arrangement, attention should be given to filling the gap between any two overlapping pipes. Since this configuration requires longer pipes, a sufficient flow rate needs to be ensured throughout the pipes. It can be a good choice for those people who have limited land space to install it as the SLGHE needs less space compared to other conventional heat exchanger systems.

Earth–Air Heat Exchanger System – Download PDF

Earth–Air Heat Exchanger System (Whitepaper Explained in Urdu/Hindi) – Youtube Video