Bamboo Construction

One of the Oldest Construction Material – yet can fulfill Modern Requirements

Bamboo is a strong, fast-growing, and sustainable material. In modern times, it can be an aesthetically pleasing and low-cost alternative to more conventional materials. Bamboo as a building material that has high compressive strength and low weight has been one of the most used building materials as support for the concrete. Bamboo’s resilience coupled with its lightweight makes bamboo an ideal material for housing in disaster-prone/earthquake-prone areas. Bamboo can withstand repetitive loadings, absorb more energy, and show more considerable deflections before collapsing, and as such, it is safer under Earth tremors. Bamboos are one of the fastest-growing plants in the world and their growth is three times faster than most other species of plants. They are a renewable and extremely versatile resource with multi-purpose usage. The low weight and its high compressive strength are the properties that make bamboo a very good construction material. Bamboo has been used as a construction material since the dawn of time. Bamboo alone can also be used to build a shelter that can withstand a long time.

It is used most commonly in areas near jungles. In Indonesia, there is a city called Bali in which houses are built primarily of bamboo. Also, bamboo construction is pretty common in Northern India.

Bamboo as a Construction Material

Bamboo as a building material has high compressive strength and low weight has been one of the most used building materials as support for concrete, especially in those locations where it is found in abundance. Bamboo as a building material is used for the construction of scaffolding, bridges and structures, houses. For bamboo to be used as a building material, it must be worked on to create the desired shape, bend and length to be used for structural or other purposes. Utilization of Bamboo for construction is achieved by a structural frame technique which is related to the same approach applied in usual timber frame design and construction. In this case bamboo, floor, walls, and roof are interconnected and often rely on the other for overall stability. Bamboo has played a vital role in the growth of enterprises and rural transformation.

Preservation of Bamboo:

A thorough treatment of Bamboo is required to protect it against insects and rot before it is put into use. Commonly a mixture of Borax and Boric acid are utilized for this purpose. Another procedure generally employed is to boil cut bamboo to remove the starches that draw insects.

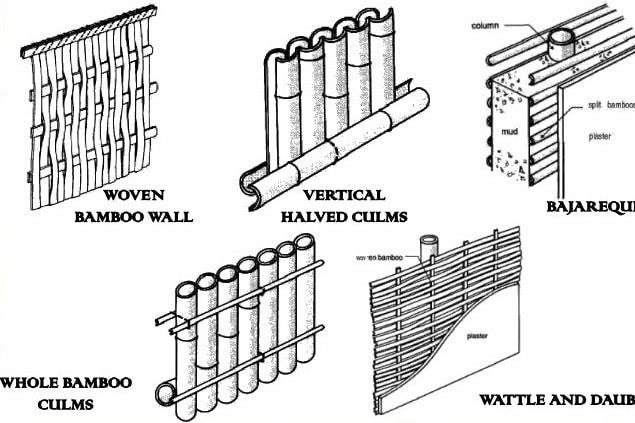

Walls Construction with Bamboo as a Building Material:

Bamboo is extensively used for the construction of walls and partitions. Posts and beams are the main elements normally constructed with bamboo to provide a structural framework for walls. They are positioned in a way to be able to withstand the forces of nature. Infill is used between framing elements to add strength and stability to the walls.

Roofing with Bamboo as a Building Material:

Bamboo is one of the best roofing materials and provides ample sturdiness to the structure. It is a proven shield against forces of nature or animals and are considerably light weighted which makes them easy to install. The bamboo roofs encompass purlins, rafters, and trusses.

Scaffolding with Bamboo as a Building Material:

Due to the advantageous properties of bearing heavy load bamboos are considered as one of the highly-endorsed materials for scaffolding even for tall structures. For the construction of scaffolding, cane extensions are obtained by lashing cane ends using several ropes. The ties are positioned in such a way that forces acting vertically downwards lodge the nodes in the lashing. This technique has immense significance since the joints can be re-aligned to the right degree.

What makes Bamboo one the of the best construction Material

- Tensile strength: Bamboo has higher tensile strength than steel because its fibers run axially.

- Fire Resistance: The capability of bamboo to resist fire is very high and it can withstand temperatures up to 4000 C. This is due to the presence of a high value of silicate acid and water.

- Elasticity: Bamboo is widely preferred in earthquake-prone regions due to its elastic features.

- Weight of bamboo: Bamboos due to their low weight are easily displaced or installed making it very easier for transportation and construction.

- Unlike other building materials like cement and asbestos, bamboo poses no danger to health.

- They are cost-effective and easy to use.

- They are especially in great demand in earthquake-prone areas.

How to Construct Bamboo House?

It isn’t easy to build a strong, durable resilient, and safe bamboo house. It is a hectic as well as complicated process. But with proper designing, perseverance, and care, we can build a low-cost, environment-friendly house that can last as long as compared to any other structure.

One type of house we can build using bamboo is of rooms made up of walls in orthogonal pattern and then using a bamboo roof over it. The step-by-step guide to build your own bamboo house is discussed below. Following these steps carefully, you can make your own bamboo house on your own with the help of a few friends or you can hire professionals to do it for you.

Step 1: Preparation of site and layout of the building:

Clean the site and 3” or 6” of topsoil is removed from the building site and stored so it can be replaced around the completed structure. There should be no grass, plants on the earth. Organic matter such as plants and roots are removed and may be composted for use in post-construction landscaping. The mixture should be free from glass plastic large stones, small pieces of wood, roots, etc. Also, compress the site if necessary to avoid settlement in the future. Compressing on loose soil is mandatory Once the site is cleaned the next step is to make a layout of your building. Layout simply means transferring the walls from plan to site. Take a limestone powder and place it where your walls are going to be on the ground.

Step 2: Foundation:

Like any other structure, we need to have a solid foundation to build something reliable and durable on it. A foundation trench is dug of about 1ft beneath the walls (bamboo walls). Little water is sprinkled over the Trench and is compacted. Then a lime sand and aggregate mixture of 4” is poured in the ratio of 1:4:8(One part lime,4-part sand,8 parts aggregates). Then stem wall is made from mud bricks and mud mortar to the height of 1.6ft from the ground level.

Step 3: Walls:

The walls of this type of house or room are not 4 sided. They are built in the orthogonal pattern. A panel is made of bamboo walls which are also braced diagonally. These panels are joined together to make a wall. These panels have a window or door opening in between them.

They are inserted directly into stem walls. Holes are made in the place where bamboos are going to fit in. The perimeter of the hole is then filled with lime sand and aggregate mixture in the ratio of 1:3:6. In this way, the walls are going to be fitted very well in the stem wall. The walls panel is then fitted with some thatch material and later on plaster is done using lime mortar or mud mortar.

Step 4: Roof:

The roofing of this type of house is a bit complicated. The roofing panel has to be bolted together with the wall’s panels. The roofing panel is made from bamboos placed diagonally as purlins. Then a green thatch roof is placed on the roof which prevents rainwater to tip inside the room and also allows the passage of air. Then a lime mortar or mud mortar is applied.

Step 5: Windows and Door frame:

For this particular type of bamboo construction that we are discussing, windows and door panels are placed in the walls panel. You make a separate wall panel for windows and doors and in that panel, there is a framework for windows and doors. The placement of these panels in their desired place is of great importance. In case, you are making your walls with the bamboo being placed horizontally, you can cut the bamboos at which window is to be placed. For the door frame, place the door frame and adjust your bamboo cutting according to it.

Step 6: Plastering

Plastering of the bamboo house is important. Without plastering, it’s just like the frame concrete structures without the brick walls. So plastering is done to provide insulation and to fill the bamboo frame structure. Plaster can be done with Limestone or mud or cement plaster.

- Lime Plaster:

Lime-based plasters are made by a mixture of lime(quicklime) and sand. They are mixed in the proportion of 1:3 (1 part lime and 3 parts sand). Lime-based plasters are the most used choice for an exterior plaster system on the bamboo house. The fantastic mixture of breathability and durability makes lime-based plaster a predictable, low-maintenance finish. A plaster pump to apply 2 to 3 coats of lime and sand plaster to the prepared bamboo walls. A final 3rd or 4th coat is often applied by hand after windows and doors have been installed. When using lime-based plaster on bamboo house walls it is best to do all the coats out of lime. - Mud Plaster:

Mud plaster can be made by mixing soil, straw, and water in suitable proportions. The ideal mixing ratio is 1:4 with 4 being the soil part and 1 being the straw part. The soil should have a minimum of 30 percent clay content. Tests should be done to get a good mixing ratio. Mud plaster is fairly easy to use, but the application process is time-consuming. The mud plaster must be smoothed by hand once it is applied, a process that may incorporate animal skins or similar materials and rounded stones to achieve a smooth surface. Pigments may also be applied in the final layer of the mud plaster.

Step 7: Flooring

Nobody wants to lay their feet on the uneven surface. The floor of the unfinished bamboo house is just as same as the floor outside the building. So, we need to provide some kind of finishing to give it a proper surface. The ground is compacted a little bit and then plaster is applied on the ground. This plaster is done with a mixture of fine clay and water. After plastering, the surface is coated with linseed oil.

Bali’s bamboo architecture is sustainable—and spectacular – Article

Lime Concrete Mix – Youtube Video

Pre-Fab Bamboo Panels – Youtube Video

Bamboo Construction – Download PDF

Rammed Earth Construction (WhitePaper Explained in Urdu/Hindi) – Youtube Video