Earthbag Construction

Realizing the Full Potential of Earthbag Construction

This method consists of filling an earth material such as sand or clay or a mixture of both in a (used for rice packing) and then stacking them in a shape (Either dome or Square). The dome technique uses the same earthbags to build a roof which is called superadobe construction with earthbag and it does not require a special foundation while to have a square roof, we need timber as a roof and it requires a trench foundation.

Earthbag construction is one of the ancient techniques to build a shelter, a basic necessity of human beings. It was primarily used to provide shelter to refugees in times of war. Since then, it’s been used to build an inexpensive, simple, and sustainable method for building structures. Earthbag buildings have been tested for their ability to endure fire, flood, wind, earthquake, and vermin, and have been used in disaster-prone zones all over the world.

Material

The material required for this type of construction is not going to cost you a fortune. It’s just present beneath your feet. Soil is used as the main construction material for this. You just need to buy a couple of things from the market to build your shelter. The materials required for earthbag construction are Sand, Clay, water, barbed wire, and polypropylene bag.

1- Earth (Sand/Clay)

It can be extracted from the location where we intend to build an earthbag house. Almost every kind of soil can be used. The good mixture shall have some proportion of clay if you are in sandy areas and vice versa. Top Soil cannot be used for this purpose because it contains impurities such as grass, leaves, etc. The soil beneath to top layer is used as it is free from impurities. More ever earth material or a mixture should be free from large size pebbles or aggregates. Aggregates having a size less than lesser than a golf ball can be allowed in the mixture.

2- Barbed Wire (Fencing Wire)

It is a fencing wire. It provides tensile strength while compressive strength is obtained from the earthbags. The ideal type of barbed wire is a 12-gauge steel wire having four points and a barb on every 5 inches. If the 12-gauge wire is not available, use the one available in the market.

3- Polypropylene Bags

Polypropylene bags are rice packing bags and are easily available anywhere. Try to use a large bag which can incorporate full span and if not available use the one which is available in the market. It should be strong enough to withstand the compression effect of temper.

Equipment Required

Tamper

Buckets

Shovels

Wheelbarrows

Polythene Sheets

Compasses

How to Make Earthbags?

Clean the site and start digging the earth. Once you dig the top layer, remove it and should not be used in the filling of Earthbags. After enough earth material is extracted, mix it with little water so that the mixture should be damped. Properly mix earth material and water. Now start filling the polypropylene bags with the mixture. The most common mixing ratio of the materials:

- Clay 25% – 30%

- Sandy Soil 70% – 75%

- Moisture 10%

Type of Structures that can be built using earthbags:

-

-

Square Structure

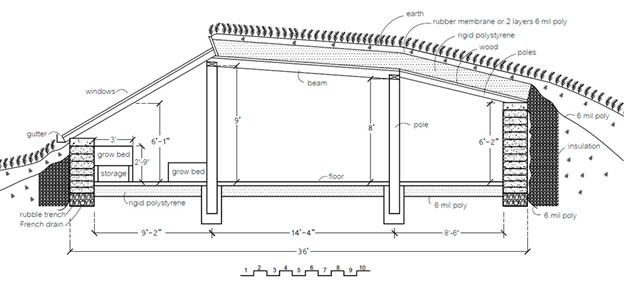

This type of structure consists of placing the earthbags in a square or rectangular pattern and then installing a wooden roof over it. This type of structure requires a special type of care in the foundation. This type of structure consists of a trench foundation, Earthbags walls, wooden beams and lintels, and a lightweight roof (Preferably timber but can be steel).

The step by step guide of construction of a square earthbag room or house is given below

- Foundation for Square structures:

This type of structure requires a special type of care in the foundation. This type of structure consists of a trench foundation, Earthbags walls, wooden beams and lintels, and a lightweight roof (Preferably timber but can be steel). The complete building process can be seen from this video from start to end. For a square foundation, Dig the earth wider than the earthbag wall (15”) and 3 ft deep. On the bottom of it, place the polythene sheet and then place the drainage pipes on it. Then add aggregates or rubble or until the 6” below the ground level. Compact it and then add a layer of gravel filled in a double polypropylene bag till the finished level of the ground. Add the barbed wire and add a second layer of 6” gravel-filled bags. This is how the foundation of the square foundation is done. The typical cross-section of this type of foundation is:- Step 1: Dig the earth and provide drainage

For the foundations, Dig the earth wider than the earthbag wall (15”) and 3 ft deep and place the polythene sheet at the bottom of the foundation. Provide pipes to allow the footing to drain after heavy rain. Also, provide a drain to keep the surface water and groundwater away from the building site. - Step 2: Add the first layer of Aggregates

Add coarse aggregates or rubble (Rubble is broken stone, of irregular size, shape, and texture. Rubble naturally found in the soil) until level about 6” below finished grade. Tamp the aggregates or rubble until it’s even and solid. There should be minimum voids between particles.

- Step 3: Add the second layer of aggregates

Fill the gravel in double polypropylene bags. Place bags on a level gravel bed 6” lower than the finished soil level. The bags should be aligned.

- Step 4: Add the barbed wire and second layer of aggregates

Place the barbed wire on top of the first layer of gravel and then add the second layer of gravel bags. Its top height should be almost 6” above the ground level to control the moisture effect. Always place the bags in overlap to the below bags. The general rule of overlays is discussed in the figure.

- Step 1: Dig the earth and provide drainage

- Walls of Square Structure

The walls are made of earthbags with the mixture discussed earlier. Always place the bags in overlap to the below bags. The general rule of overlays is discussed in the figure.

- The roof of square structure

The walls are made of earthbags with the mixture discussed earlier. Always place the bags in overlap to the below bags. The general rule of overlays is discussed in the figure.

- Plastering

Plastering of earthbags structures can be done by lime plaster or mud straw plaster. Since there is a spacing between the two layers of earthbags which are placed vertically, it is important to fill those spaces with plaster. The earthbags alone cannot withstand the extreme rainy conditions so plastering should be done as it provides weather resistance as well as structural strength also.

- Foundation for Square structures:

-

-

Dome Structure

Dome structures are also called superadobe structures and were introduced by Nadir Khalili in the 1980s.In this structure, a separate wooden or steel roof is not required and the roof is built in the form of a dome.

- Foundations for Dome structures

Perhaps the most integral part of any structure is its foundations. If foundations aren’t laid accurately the whole building can collapse. Make a trench in the ground of the height of two earthbags and then simply place two layers of earthbags bonded together with the barbed wire. Cover these two layers in a plastic sheet to stop any water from coming into the foundations. - Walls, Doorway, Windows, and Roof

The walls of dome structures are not vertical. The earthbags are placed in a circular shape following the lancet arch. There is no need for a special roof for this type of structure. The geometry and placement of earthbags in the case of dome structures are of great importance. Every earthbag should be laid following the principles of superadobe structures. The dome structures follow an arch shape at every layer of earthbags. - Plastering of Dome Structures

Perhaps Plastering of earthbags structures can be done by lime plaster or mud straw plaster. Since there is a spacing between the two layers of earthbags which are placed vertically, it is important to fill those spaces with plaster. The earthbags alone cannot withstand the extreme rainy conditions so plastering should be done as it provides weather resistance as well as structural strength also. - Flooring

Nobody wants to lay their feet on the uneven surface. The floor of unfinished cob rooms or buildings is just as same as the floor outside the building. So, we need to provide some kind of finishing to give it a proper surface. The ground is compacted a little bit and then plaster is applied on the ground. This plaster is done with a mixture of fine clay and water. After plastering, the surface is coated with linseed oil.

- Foundations for Dome structures

A slideshow presentation on Earthbag Construction – Youtube Video

How to build an earth-friendly home with Earthbags – Youtube Video

Woman builds Breathtaking Sustainable Dome Homes with beautiful interior – Youtube Video

Earthbag & Architecture – Youtube Video

Earthbag Construction – Download PDF

Earthbag Construction (Explained in Urdu/Hindi) – Youtube Video